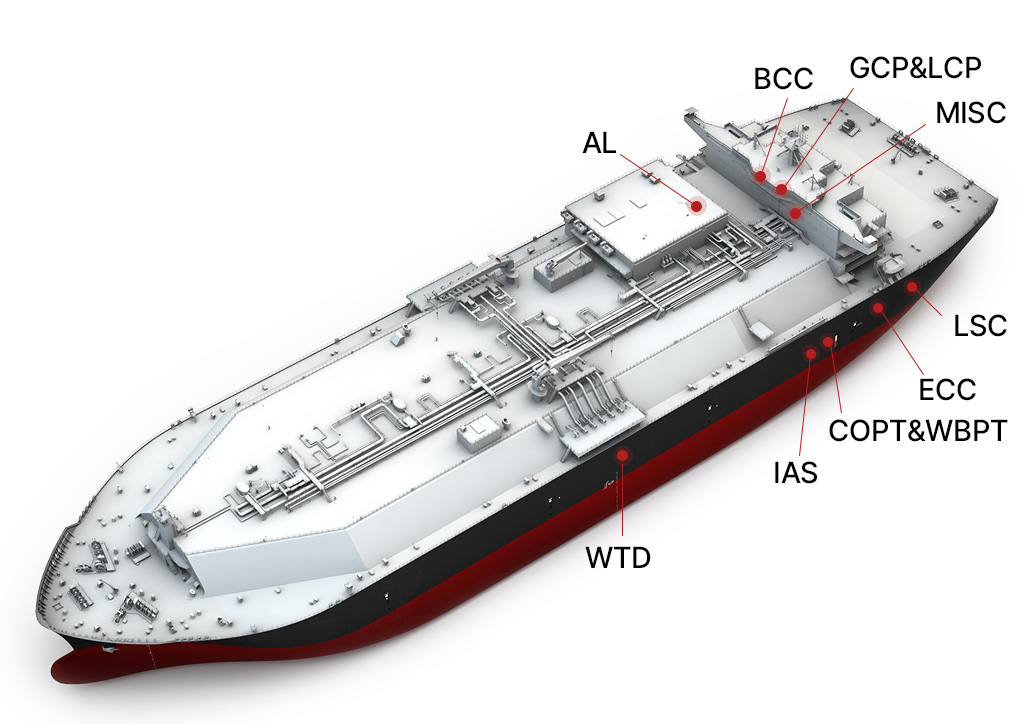

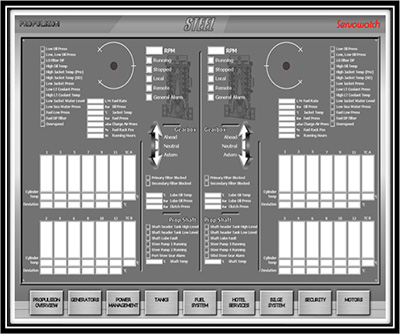

HME offers various automation system for easy control by operators and stability.

These features are proven by a device driving method, structural from of the device and installation method.

PARTNERSHIP With ROLLS ROYCE As ROLLS ROYCE (in the UK)'s strategic partner, HME offers device commissioning, I/O card production and engineering technology. Application Package Integrated platform management system Integrated bridge system Alarm monitoring system Integrated ship management system

HME’s automation systems, which offer easy control and stability, can be installed and supplied in a customized console.

The console is designed and produced by taking the required protection level, material and operation form into consideration, and it is

available in one-man bridge, piano and desk types in accordance with the installed place.

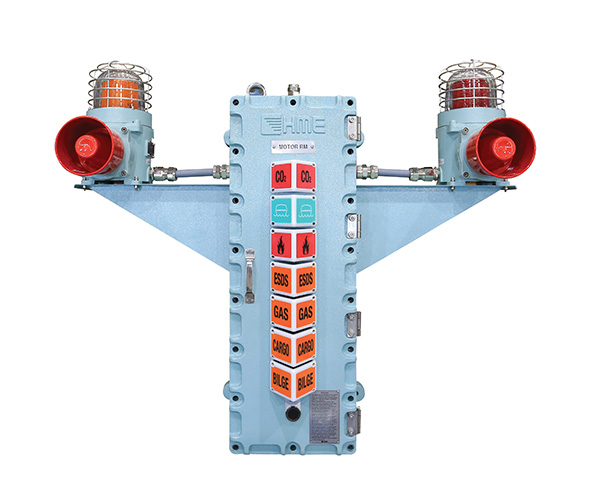

LSC (Light Signal Column) is installed in engine room or on-desk of vessel and transmit a variety of alarms occurred during ship sailing to operators through the visual and audible alarm devices.

HME’s LSC is the excellent product that is designed to satisfied to IMO regulation A.1021(26) "CODE ON ALERTS AND INDICATORS" and took a MED certification.

Main Function HME’s group light control panel is a device that can control the ship sailing light, the ship signal light and the ship indicator required in various classifications to prevent collision in advance and secure safety in accordance with the COLREGS. It is composed of the navigation light control panel, signal light control panel and outdoor light control panel. Main Feature HME’s navigation light control panel is manufactured to fit the IMO regulation Res.MSC 253(83) “Navigation light & controller” regulation and it is an excellent product.

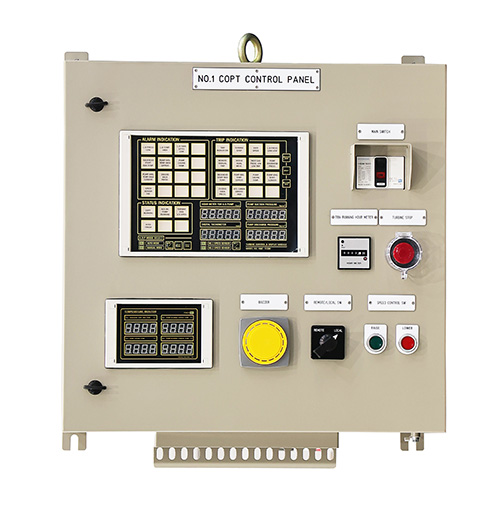

Main Function & Main Feature Cargo Oil Pump Turbine Panel is a control panel for alarm, trip and rpm indication. And it transfer information on the status of Cargo Oil Pump Turbine to Engine Control Room or Cargo Control Room.

Main Function & Main Feature AIRLOCK ALARM SYSTEM is a warning device for preventing to be spread the gas from dangerous compartment to outside and it is installed at entrance of dangerous gas generation compartment in ship. Also, when entering the dangerous compartment, it monitors pressure abnormalities and opening or closing status of doors. It provides audible and visible alarm when detecting abnormalities.

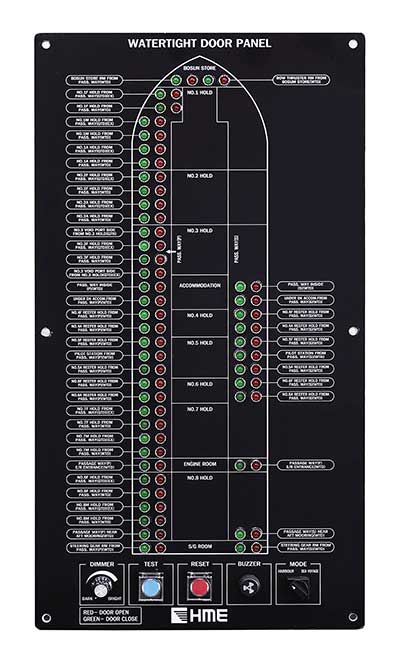

Watertight Door Indication panel is a panel to inform state of open or closed of the Watertight Door in the ship with audible and visible alarm, installed in wheel house. And it transmits state of Watertight Door to the Voyage Data Record (VDR) and Alarm Monitoring System. And it is applied serial communication interfacing using RS-422 method. Customer order-specific production is also possible and active service is provided for offshore and ship special requirements.

MISC (MISCELLANEOUS COMMOUNICATION SYSTEM) is a device to transmit warning or calling signal with audible and visible alarm in the ship. And it is installed in on-board hospital room or reefer chamber to call crew or used as audible and visible warning device.

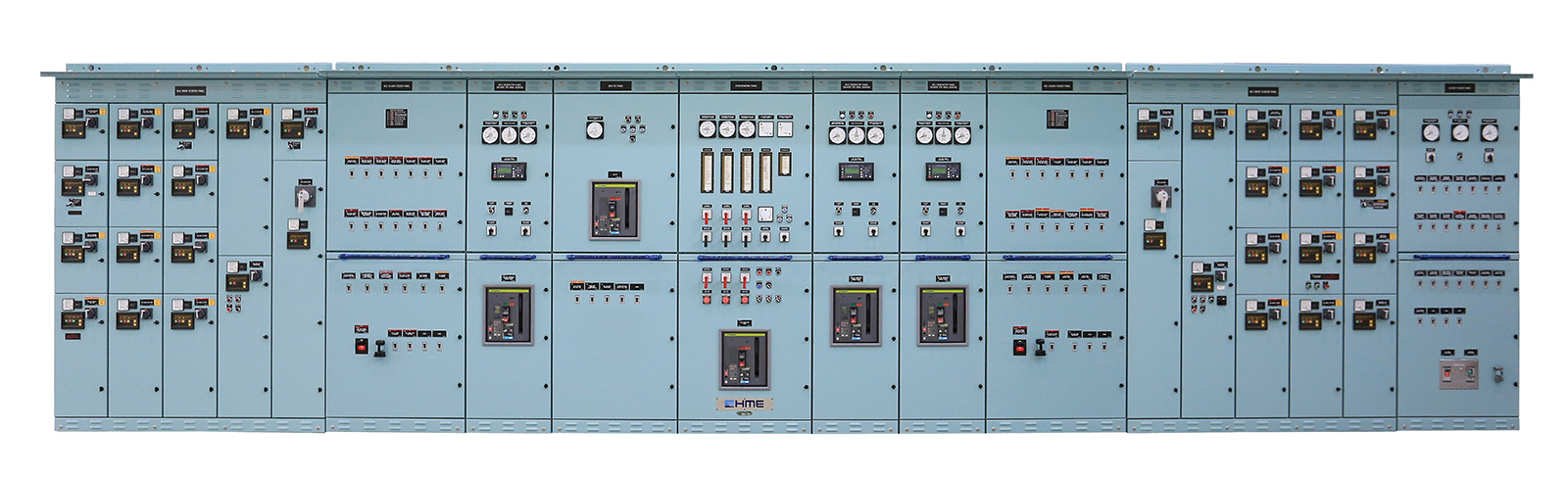

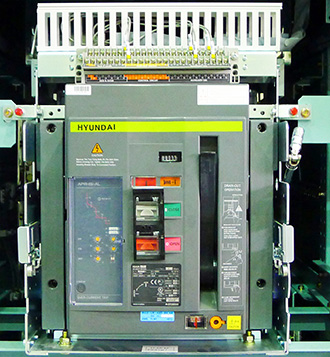

HME’s Main Switch Board is a device that stably supplies power to each load by distributing from generator. It is designed and produced within all relevant international regulations and offers high product stability through strict inspection.

Generator’s protective function It can safely protects the generator from all possible abnormal states, such as over current, short circuit current and differential current that could occur in operating the generator

Power management function It controls the optimum operation of the generator by analyzing the power amount required in every process and offers diverse functions that can quickly supply alternative power in abnormal conditions. Moreover, it offers a variety of applications for a parallel operation of generators and a parallel operation of the shaft generator.

Integrated management solution It offers an effi cient management solution that monitors and controls each generator’s power requirement and other alarms through the remote I/O card. The remote I/O card supports diverse communication methods and it is compatible for each protocol.

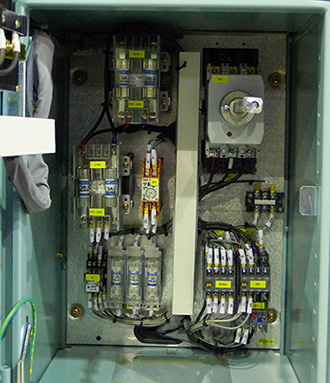

Motor Control Center is the power equipment to operate and monitor various pumps and fans needed in shipbuilding and plant industries. HME’s Motor Control Center is designed and produced to satisfied with all of the relevant international rules and regulations and having the highest product safety through the process of the strict review.

Motor protection function The motor control center is basically equipped with a protective function against over current that could occur in motor operation. And it has the stand-by function which is enables to Back-up operation by steadily monitoring the abnormal situations of motor (Power fail / Over current / Low Pressure) in the motor operation.

Integrated management solution It offers an effi cient management solution that monitors and controls each generator’s power requirement and other alarms through the remote I/O card. The remote I/O card supports diverse communication methods and it is compatible for each protocol.

Main Function It steadily and alternatively supplies power to each part during the back-up time in the event of the main power’s blackout. Main Feature Battery monitoring system It offers optimum charging method that can minimize the Battery life reduction in a high temperature by monitoring the temperature and condition of Battery in real time and by adjusting the charging voltage of Rectifier according to the detection result. Specialized technical skills for various requirements in the offshore and plant fields. Offering active service for the offshore and ship’s specialized demand in addition to custom-made production.

Main Function It supplies power to the parts that are supposed to be in operation during blackout. It supplies DC power to the parts unlike UPS (uninterruptible power supply). Main Feature Specialized technical skills for various requirements in the offshore and plant fields. Offering active service for the offshore and ship’s specialized demand in addition to custom-made production.

It is closely related to the eco-friendly business that prevents power loss and reduces carbon dioxide emission by controlling the speed of the induction motor depending on recent environmental factors (temperature, humidity etc.) And it is used as an important device that converts produced power into usable electricity. it is also used in the renewable business, using wind and solar energy.

PARTNERSHIP With DANFOSS HME has signed a partnership agreement with DANFOSS Corporation in Denmark and we have been researching and developing various technical solutions of VFD applied to different vessels by collaborating with major shipbuilders in Korea. Main Function VFD is a controller that enables variable adjustment of the inputted AC power to frequency which user want. It is mainly used to control the speed of the induction motor through frequency control.

Application case for vessels and Offshore Motor speed control solution in accordance with the temperature of C.S.W pump or E/R fan Parallel drive solution with S/G and D/G Parallel switchover solution between shore connection and the generator Power distribution flame (generator, motor etc.) reduction solution through the super soft start function Electric propulsion solution